Why is a boiler service important?

Having your boiler serviced regularly can save you money in the long run by ensuring your boiler is running as efficiently as possible. A service shouldn’t take more than an hour and costs around £80-140 on average depending on what type of boiler you have. This should be carried out once every year if possible, especially if you have an older boiler as they can be working 30% less efficiently – costing you money!

A boiler service should always be carried out by a professional Gas Safe engineer – it may be wise to check the status of your engineer on the Gas Safe register.

What issues can a boiler service resolve?

The most common problems caused by a boiler which can be resolved include:

- Leaking

- Low boiler pressure

- Boiler noise

- No heating or hot water

- Radiator faults

- Frozen condensate pipe

- The boiler not responding to the thermostat

- Pilot light keeps going out

- The boiler has no power

If you are concerned that your boiler is experiencing one or more of the above issues – this article goes into more detail about each issue.

What are the benefits of a boiler service?

Save money and keep bills as low as possible – As previously stated, a drop in the efficiency of your boiler can cost you extra money, as much as £200 extra per year! With energy bills rising this may be a quick and easy fix to ensure you aren’t losing unnecessary money.

Avoid emergency repairs – Boiler repairs can be expensive and replacing your boiler can cost even more! Emergency call-outs usually always cost much more than a regular service and so are best to avoid.

Avoid life-threatening malfunctions such as carbon monoxide leaks – Carbon monoxide leaks are very dangerous and in the worst cases can even cause death. Carbon monoxide leaks are caused when boiler fuel is not completely burnt due to a lack of oxygen. This article from Vaillant goes into detail about the symptoms of carbon monoxide leaks.

What will happen during my boiler service?

A visual inspection – Here the engineer should look at the boiler for visual signs of damage, corrosion or leaks and check that the boiler meets all the required standards. Here the engineer should also ignite your boiler and run it to check it is working as it should.

Check internal components – This requires the boiler case to be removed to check the burner, heat exchanger, main injector and spark sensor probe. This stage also gives the engineer a chance to clean the inside of the boiler if that is required.

Flue check – The pipe from your boiler to the outside of your property should also be thoroughly inspected to ensure there are no obstructions and that it is well fitted for purpose. The boiler flue is an essential part of a boiler which allows waste gases to be disposed of safely. There are various regulations for the positioning of a boiler flue which can be seen here.

Gas rate – This measures the volume of gas used by the boiler. To pass this must be within the limits allowed in the boiler manufacturer’s standards. This part of the service will indicate how efficiently your boiler is working. The more efficiently your boiler is running the less it will cost to run.

British gas has an article explaining how to improve the efficiency of your boiler here.

Operation and control – Here the engineer should check all the functions of the boiler, controls and check that safety devices are working as they should. If they find any safety defects the engineer will share the full details with you and fix the problem where possible in line with the Gas Industry Unsafe Situations Procedure.

Boiler tightness check – This check will measure whether or not there is any gas escaping from the boiler.

Boiler safety checks – Here the engineer will check how the boiler is fitted ensuring it is stable. The combustion and case seal should also be checked ensuring no leaks as previously mentioned and the inside of the boiler will be cleaned.

System pressure checks – The working pressure is checked at 3 points to ensure it is working correctly including the boiler, inlet burner and gas meter. Working pressure is the normal operating pressure that a component is set to work at continuously. This part of the service will identify if there are any problems with water mixing with the gas supply, if the pipes are the wrong size and if there are any blockages.

Cylinder check – If you have a more conventional or older boiler, the heating cylinder may need to be checked. The easiest way to check this yourself is to run the cold tap and notice if it has an odour.

Conduct a record of findings – The engineer should ensure they make a record of each test carried out and the results. This will be helpful to keep a log for future inspections.

This is called a Benchmark service record and it is a requirement to complete this checklist in full when installing or servicing a boiler.

If the boiler does not meet building or legislation regulations the engineer should inform you once they have completed their checks. Ensure that the engineer properly explains any repairs or maintenance that may be required as well as checking that any part sussed come from a reputable manufacturer.

Is an annual boiler service mandatory for me?

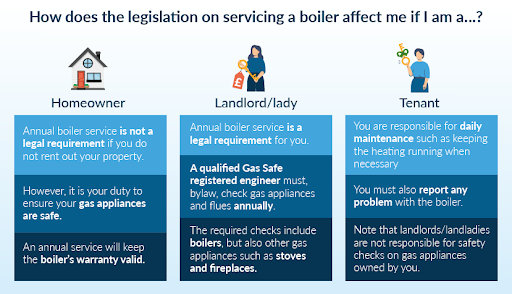

This infographic from Boiler Guide shows where an annual service is required.

It is important to be aware of the laws around boiler checks – especially if you are a landlord/lady or if you have any properties in which you are not currently living in.

To find out more about boiler installation, repairs or services check out our website and get in touch with a member of the team today.